Battery Testing Chambers

04.27.2023

Rechargeable lithium batteries have been the choice for portable electronic devices. As they now become important for electric vehicles, reliability and safety become paramount. The batteries must perform well in hot and cold conditions, while not posing a hazard due to leaking or exploding.

Through temperature testing with ESPEC chambers, the batteries’ ability to withstand environmental extremes and stress can be identified safely.

Common test standards for secondary lithium-ion battery cells or modules:

- UL 1642 - Standard for Lithium Batteries

- UL 2054 - Household and Commercial Batteries

- IEC 62133 - Safety requirements for portable sealed secondary cells

- IEC 62660-2 - Secondary lithium-ion cells for the propulsion of electric road vehicles - Part 2: Reliability and abuse testing

- SAE J2464 - Electric and Hybrid Electric Vehicle Rechargeable Energy Storage System (RESS)

For more information on Battery test standards, see Battery Test Methods and Specifications.

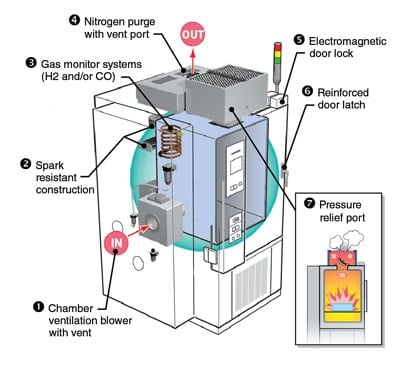

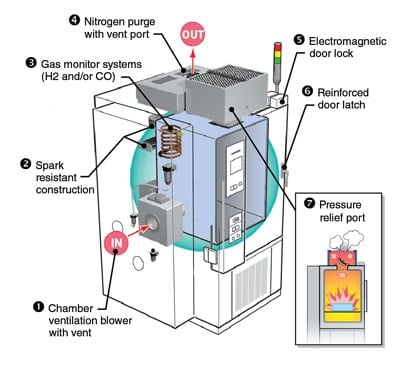

Safety features per your needs

Because battery failure is a real risk (and sometimes its a desired outcome), environmental chambers need safety systems to protect from harmful explosions and ensure operator safety.

Because battery failure is a real risk (and sometimes its a desired outcome), environmental chambers need safety systems to protect from harmful explosions and ensure operator safety.

Of greatest risk is the release of gases from a battery, which may ignite on their own, or by the test chamber’s heaters. Special low-temperature heaters are recommended, but additional precautions may be necessary. By monitoring the battery for thermal runaway, the chamber may be shut off and an alarm made prior to an explosion.

Based on your testing needs and safety requirements, ESPEC can help with the following options to create a complete testing system.

Protection Options

- Chamber ventilation blower with vent port— Ventilation purges chamber with ambient air, activated by a gas monitoring system

- Spark resistant construction— Fan blades and motor port made of spark resistant Aluminium

- Gas monitor systems (H2 and/or CO)— Monitors the chamber workspace for hazardous gas, includes an alarm and light

- Nitrogen purge with vent port— Purges nitrogen into chamber to reduce the oxygen content of the workspace air

- Electromagnetic door lock— Prevent operator access during operation (500 lbs. of holding force)

- Fire detection system with vent port— Detects fire and shuts down the chamber, includes an alarm and light

- Product overheat with product sensor— Protects test load from temperatures that are higher than desired

- Chamber door switch— Inhibits chamber operation if chamber door is open

- Product drip tray— Removable/replaceable tray to contain any corrosive leaks

Safety Options

- Reinforced door latch— Designed to withstand pressure increase due to explosion

- Pressure relief port— Quickly relieves pressure inside of chamber

- Fire suppression system— Suppresses fire by flooding workspace with CO2, use with fire detection system

- Port plug restraint— Cover that restrains port plugs from flying out due to over pressurization

Because battery failure is a real risk (and sometimes its a desired outcome), environmental chambers need safety systems to protect from harmful explosions and ensure operator safety.

Because battery failure is a real risk (and sometimes its a desired outcome), environmental chambers need safety systems to protect from harmful explosions and ensure operator safety.