In this article, we are covering the Spray Test for the resistance of surface wetting in materials testing, by focusing on the most common questions we are asked by textile testing professionals and our customers.

The Spray Rate Test is a test to determine the water repellency of materials using a ‘shower test’. Due to the nature of the Spray Rate Test, it can be often mistaken for the ability to predict the waterproofness of materials.

“The test does not measure the penetration of water through fabric; instead it determines the resistance of any fabric, which may or may not have been given a water-resistant or water-repellent finish, to surface wetting by water”

The following standards should be followed and complied to:

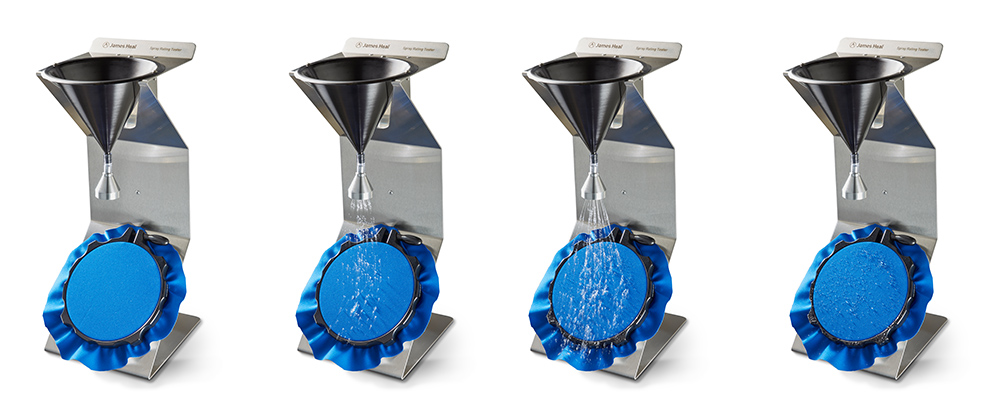

A specified volume of distilled water is sprayed centrally onto an inclined test specimen, and its spray rating is determined by comparing the appearance of the specimen with descriptive standards, or the AATCC Spray Test Rating Chart.

The assessment of spray rating is determined by comparing the appearance of the tested specimen with descriptive standards and photographs, and the AATCC Spray Test Rating Chart is available for this purpose.

A Spray Rating Tester is a simple instrument for evaluating the ability of waterproof fabrics to repel water. James Heal’s Spray Rate tester combines simplicity with serious functionality – the instrument comprises a stainless steel framework, incorporating a funnel. The spray nozzle is mounted on the neck of the funnel. The precision spray nozzle contains 19 holes – one central hole surrounded by two concentric rings of 6 and 12 holes respectively.

“James Heal’s Spray Rate Tester ensures accurate and reliable water repellency testing with its stringent quality control of the nozzle hole pattern, combined with accurate height setting above the specimen. These ensure a consistent spray flow and formation, critical to the requirements of the International standards.”

A variety of fabrics can be tested, from apparel to performance materials, such as:

The Spray Rate Test is a well known and standardised test, and the basic test can be used to provide a consistent and repeatable differentiation between different water repellent fabrics, but it’s not without its pitfalls. A significant critique of this test is that it is ‘subjective’ meaning the interpretation of results could vary from one user to the other – leading to a degree of variability in results. Therefore, its effectiveness is enhanced when measuring the percentage of weight increase of the test specimen, before and after the test, to provide a more objective assessment and measure of performance.

“The effectiveness of the spray test is enhanced when measuring the percentage of weight increase of the test specimen, before and after the test, to provide a more objective measure of performance.”

Furthermore, as a static test, it is useful for assessing the basic repellency performance of a fabric, but it’s not fully representative of the ‘wearer use’ of water repellent apparel.

Therefore we recommend that to determine the overall repellency of a fabric, that the Spray Rate Test is done along the Bundesmann Rain-Shower Test. The Bundesmann test is one of the most representative of real ‘wearer use’ conditions, because it uses a greater distance between the nozzles and test specimens, along with a prolonged flow of water. It also has the advantage of assessing both the surface wetting and water penetration of a fabric.