To guarantee the perfect product delivery to final customers, a previous packaging behavior analysis against vibration is needed. Thus, the innWave family is the best solution to optimize the packaging design. This family includes the following vibration systems:

Our innovative and patented technologies assure more realistic simulations to perform vibration tests such as ISTA 6-Amazon.com procedure, that all Amazon vendors and distributors must perform in order to get the Amazon Frustration Free Packaging certification.

VIBRATION SYSTEMS FEATURES

More realistic simulations

> The system performs vertical vibrations plus pitch and roll movements, so simulations are closer to reality.

Independent control

> Completely independent module controller by Real Vibrations.

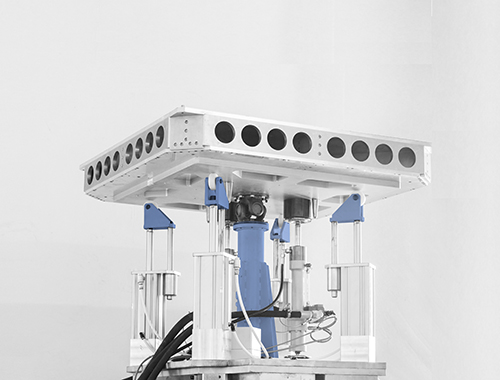

VERTICAL VIBRATION + PITCH & ROLL SYSTEM ADVANTAGES

This solution has the features of the Vertical Vibration System and includes:

The simulation of transport by road, train and plane

> Vertical frequency ranges up to 200 HZ. > P&R frequency range up to 25 Hz. > P&R rotation ± 5º.

A special system for simulating maritime transport

> The system can simulate maritime transport movements with high accuracy.

PITCH & ROLL MODULE ADVANTAGES

> More affordable than a complete VV, P&R system.

> Doesn’t need an extra foundationor seismic mass.

> Independent HPU.

> Customized design to fit in your machine.

> More realistic simulations.

VIBRATION TESTS SUPPORTED