The amount of heat that is generated internally in a shaker by moving test articles can be considerable. It is critically important that the temperature of the working components in your shaker are controlled so that excessive heat does not build up and damage your shaker or your test article.

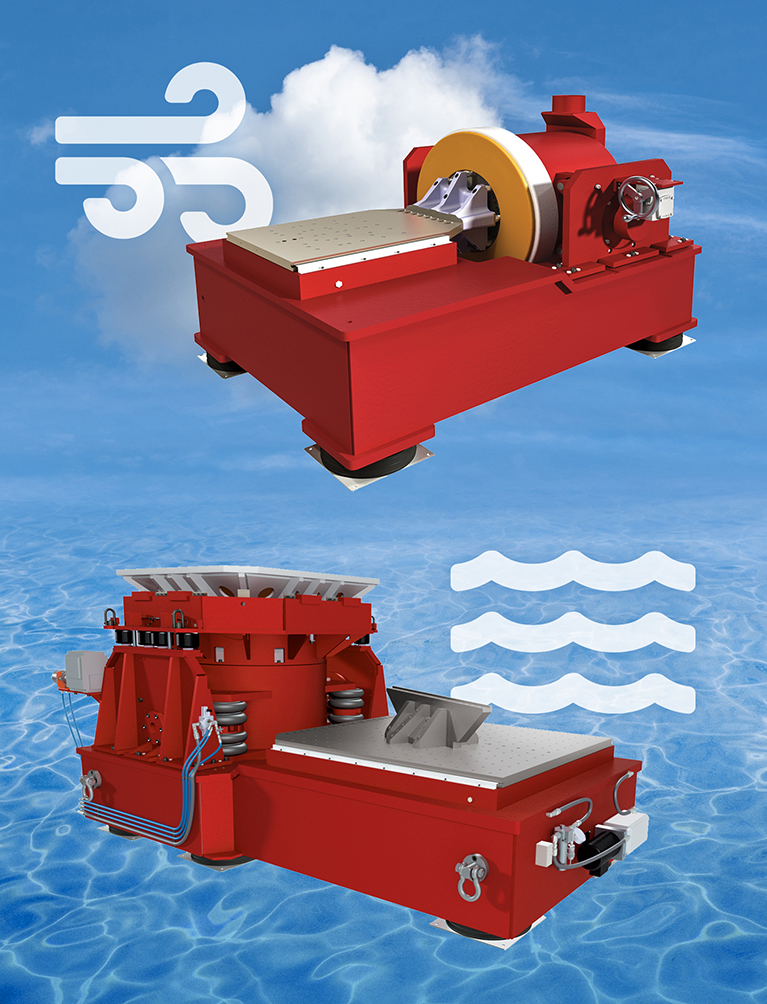

There are two primary means of keeping your shaker cool: forced air and cooled water. Each of these techniques have their advantages and disadvantages.

A large blower is used to draw air through the shaker allowing the cooler air to pull heat out of the shaker. This is a pretty straight forward technique, but it is not without its drawbacks. Moving so much air through a shaker is not only noisy, but it can complicate the HVAC needs in a building. Additionally, the hot air being pulled out of the shaker needs to be exhausted somewhere.

There are many situations where air-cooled shakers are not desirable. Clean rooms can be seriously challenged when large amounts of air are being pulled from the room. The air needs to be replaced somehow and that air needs to be highly controlled so that it does introduce any contaminants. Additionally, some test sites work with highly explosive materials, and they do not want to risk exhausting this to the outside. Lastly, blowers can introduce a lot of noise into a system and into its environment. The forced air moving through the shakers may introduce unwanted vibration into test articles that can be readily detected during the testing of sensitive equipment. While blowers can often be moved to locations some distance away from the shaker, they commonly produce in excess of 90 dB (A) at 1m.

Water cooling sounds a lot more complicated, but it’s really not and chilled water draws heat out of shakers very efficiently. Basically, chilled water is pumped through the critical parts of the shaker and draws the heat out. A cooling unit contains the pump and recirculates distilled water throughout the shaker. The heated distilled water is then cooled using the chilled water from the facility in the cooling unit. No air needs to be circulated through the shaker.

The advantages of a water-cooled shaker are considerable. By using a water-cooled shaker, you can eliminate significant amounts of environmental noise, reduce the burden on the HVAC system, operate easily in a clean room environment and eliminate any potential issues in exhausting explosive or potentially toxic particles into another environment.

The Data Physics line of water-cooled shakers range from 16k lbf all the way up to 50k lbf. Let’s discuss how water-cooled shakers can keep you from losing your cool.