Elevating Avionics Testing

Broad compliance across industry standards ensuring reliability and safety for avionics systems

Ensure Reliability with EA's Advanced DC Power Supplies and Electronic Loads

Aircraft electronics, including avionics, face some of the most challenging power conditions. Rigorous testing is required to validate their resilience against over-and-under voltage conditions, power dropouts, and voltage transients, as outlined in MIL-STD-704 and MIL-HDBK-704-7/8 standards.

Elektro-Automatik offers a versatile range of DC power supplies, electronic loads, and bidirectional power supplies designed for these tests. With features like auto-ranging, onboard arbitrary waveform, and function generation, EA’s PSI, EL, ELR, and PSB series can output up to 2000V. This ensures comprehensive testing to simulate real-world conditions, guaranteeing the reliability of avionics and other airborne equipment even under extreme conditions.

Related Products

Application Solutions

Future Proofing Avionics with DC Electrified Systems

Energy Supply & Storage: Innovations in liquid hydrogen fuel and fuel cell battery management are essential for delivering consistent power during peak take-off and moderate in-flight conditions.

Engine Weight & Size: The physical dimensions and weight of engines and battery power systems are critical factors in the design process.

Extreme Conditions: New systems must be robust enough to withstand a range of harsh conditions, from temperature fluctuations and humidity to high acceleration and vibration.

Hazardous Materials: Safe handling and containment of materials like lithium batteries and liquid hydrogen, which is stored at -250 degrees Celsius or as gas under 700-bar pressure, are paramount.

Power Conversion & Distribution: Engineers are working on versatile power conversion systems that can adapt main DC supply grid levels of 700-1000V to lower ranges suitable for various airplane systems, such as instrumentation, air conditioning, and critical landing gear controls.

The PSB bidirectional programmable DC power supply can effortlessly transition between charging and discharging batteries and comes equipped with various test functions compatible with the PSB, PSI, EL, and ELR series. Whether you need standard or custom charge and discharge cycles, EA provides the ideal equipment and expert guidance for effective and safe battery testing.

Pioneering DC Power in Aviation

High-Power DC Electric Propulsion: Development of megawatt-capable electric turbines for propulsion.

Passenger Comfort Systems: Innovations in heat/air conditioning, lighting, and infotainment systems.

Critical Aircraft Systems: Heavy-duty solutions for landing flaps, braking, and landing gear.

Avionics Instrumentation: Advanced instrumentation for navigation and control.

Battery and Fuel Cell Technologies: Focus on enhancing battery capacity and efficiency for long-haul flights, often through the integration of fuel cells and non-flammable battery boosters.

Beyond aircraft systems, the industry is also redefining the green aviation ecosystem and hydrogen supply chain. This includes hydrogen production via electrolysers powered by solar installations and the transportation of hydrogen fuel to airports using emerging electric-powered trucks. EA Elektro-Automatik’s technologies are instrumental in this transformative journey towards sustainable aviation.

Testing the Future of Flight

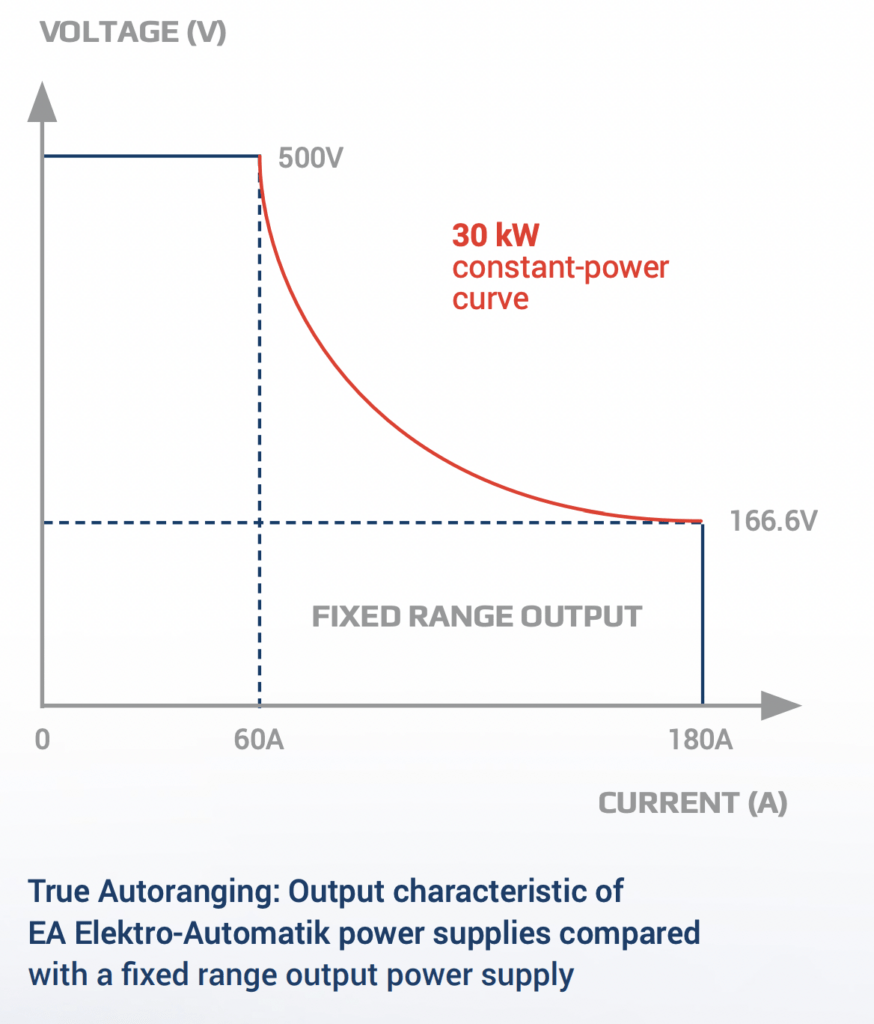

True Autoranging Capability: EA’s power supplies feature true autoranging, allowing engineers to test a broader spectrum of devices. These supplies can deliver full power output across a wide range of voltages and currents, even down to 1/3 of their maximum capabilities. This versatility results in cost savings, reduced test rack space, and lower cooling requirements.

Bidirectional Regenerative Power Supplies: Unique to EA Elektro-Automatik, these bidirectional supplies recover energy from the device under test and feed it back into the grid with 96% efficiency during long-term testing. This feature offers a quick return on investment.

Built-in Function Generator: Eliminating the need for an external signal generator, EA’s built-in function generator allows for easy modulation of the power supply output.

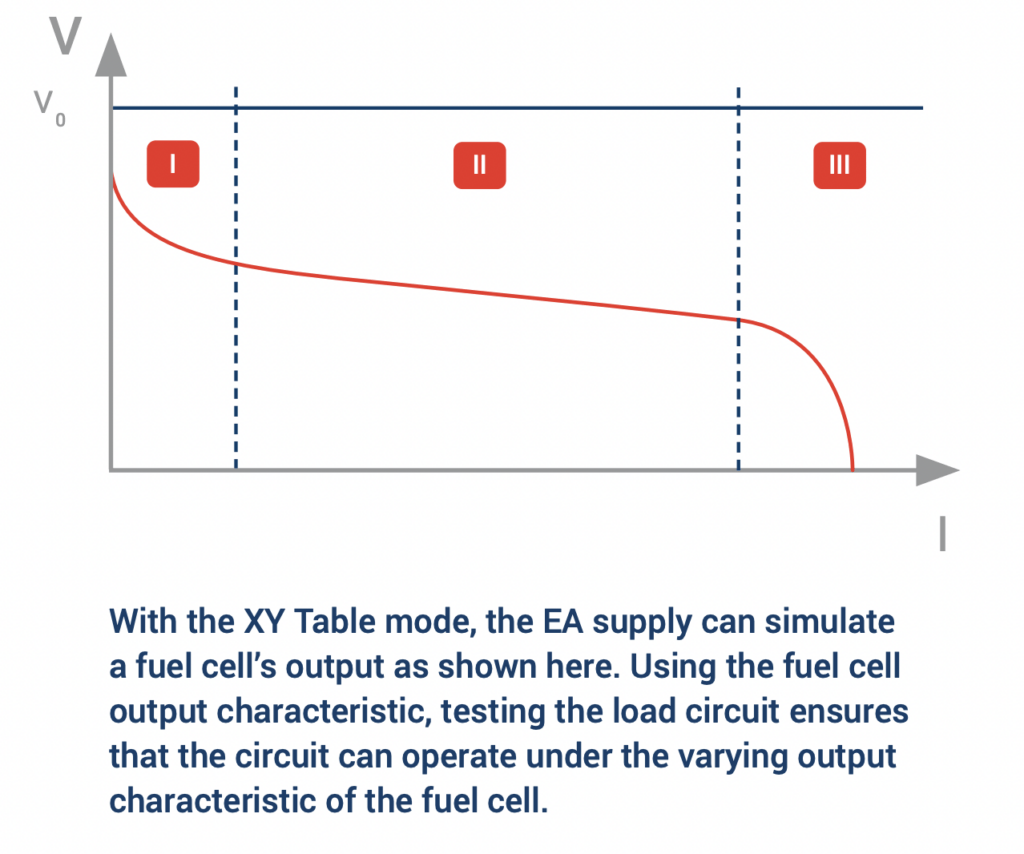

Electronic Loads with Energy Recovery: EA’s electronic loads come equipped with autoranging, a built-in function generator, and regenerative energy recovery. These features enable comprehensive testing of fuel cell power sources, simulating various load states, including failure scenarios.

MIL-HDBK-704-7 270 VDC Abnormal Voltage Transients

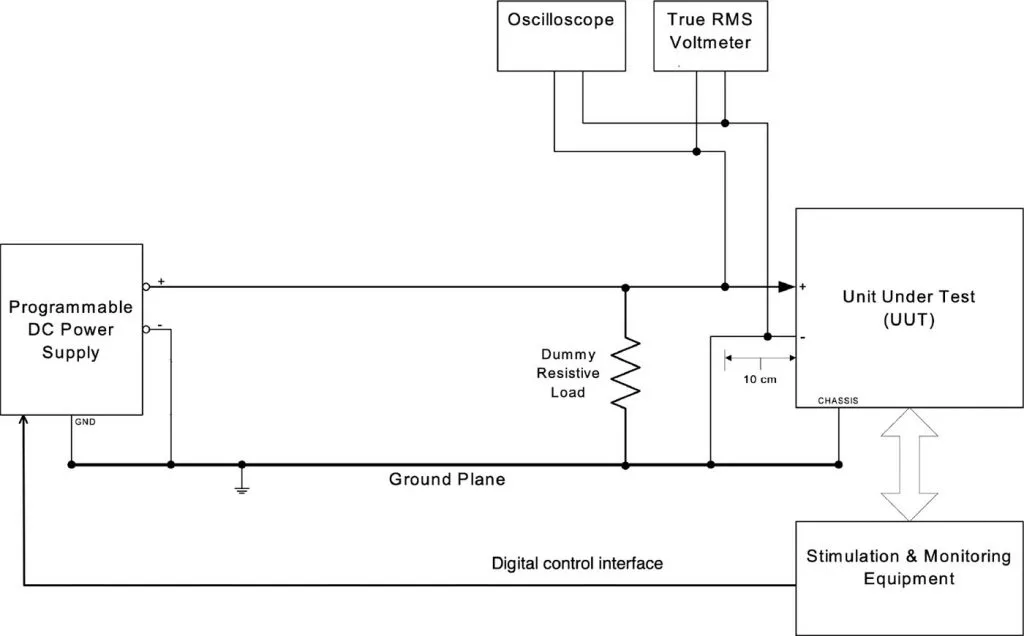

EA’s DC power supplies come with an integrated arbitrary function generator, allowing you to program specific voltage transients for the test. These supplies can deliver up to 15 kW and feature minimal EMC emissions. Additionally, they offer galvanically isolated connectivity options like USB, Ethernet/LAN, or GPIB, making them ideal for automated avionics testing scenarios.

With EA Elektro-Automatik’s advanced DC power supplies, you can confidently conduct MIL-HDBK-704-7 compliant tests, ensuring your avionics equipment meets the highest performance and safety standards.

EA Advantages

MIL-HDBK-704-8 28 VDC Power Failure

The Power Failure Test, as specified in MIL-HDBK-704-8’s Method LDC601, is an essential procedure for evaluating the durability and performance of 28 VDC avionics equipment during intermittent power outages. This test involves cutting off the power supply to the unit under test for predetermined durations, then restoring it and conducting a thorough performance assessment to confirm the equipment’s reliability and integrity. EA Elektro-Automatik’s DC power supplies are designed to meet these rigorous testing conditions.

Equipped with a digital control interface, EA’s DC power supplies can handle power-off times of 100 ms, 500 ms, 3 s, and 7 s, as required by the test. These supplies can deliver up to 15 kW and feature low EMC emissions. They also offer a range of galvanically isolated connectivity options, including USB, Ethernet/LAN, and GPIB, making them ideal for automated avionics testing scenarios.

With EA Elektro-Automatik’s specialized DC power supplies, you can perform MIL-HDBK-704-8 compliant Power Failure Tests, ensuring your 28 VDC avionics systems meet stringent performance and safety criteria.

EA Advantages